Occupational Health & Safety

Policy on Occupational Safety and Health

Based on its stance of respecting human life and ensuring safety, as laid out in the Group Corporate Philosophy and Corporate Stance, the Yamato Group thoroughly adheres to its philosophy of placing safety first and business second, positioning respect for human life as a priority at all times.

Occupational Safety and Health Management Regulations

The Yamato Group has provided occupational safety and health management regulations to each Group company. The purpose of the regulations is to set out necessary matters related to safety and the health of employees based on relevant laws and regulations, such as Japan’s Labor Standards Act and the Industrial Safety and Health Act, to enhance safety and health activities in the Company, to clarify the necessary basic matters for preventing occupational accidents, to promote the creation of comfortable workplaces for employees, and so forth. The safety and health management regulations include six items: Safety and Health Committee, Safety and Health Management System, Safety and Health Plan, Safety and Health Education, Health Management, and Safety and Health Standards.

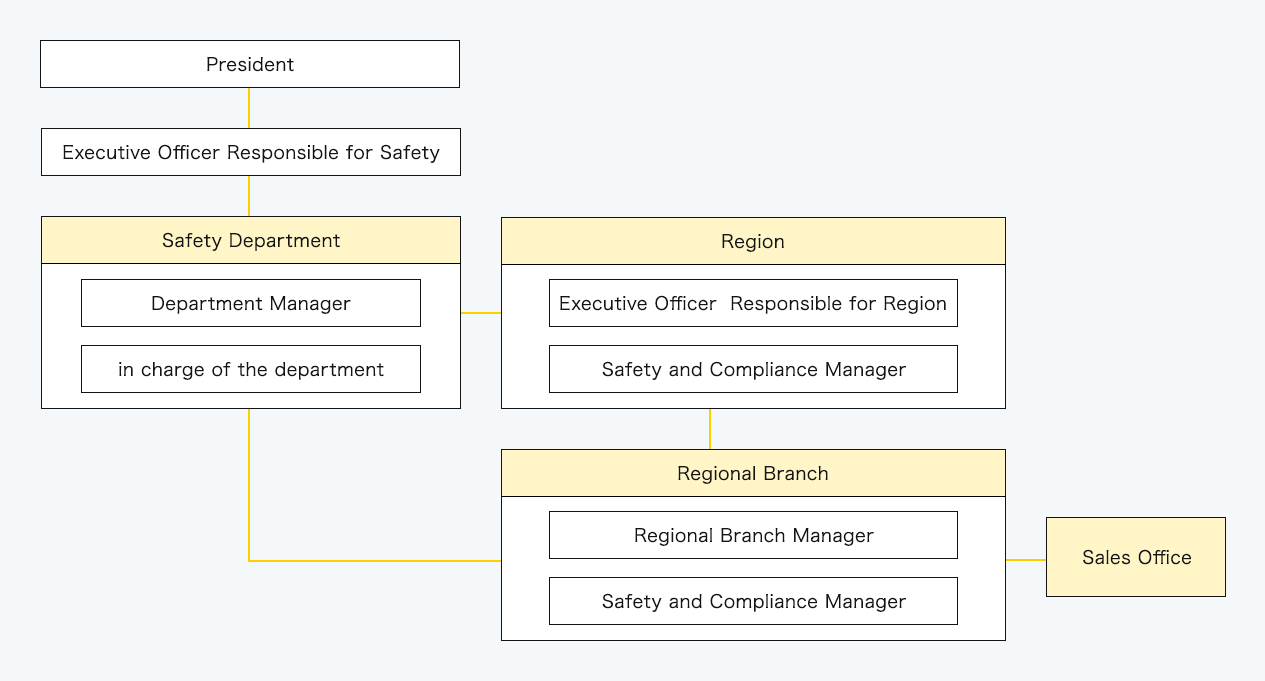

Promotion Structure

Yamato Transport has established a Central Safety and Health Committee, chaired by the executive in charge of occupational safety, to deliberate on necessary matters for safe business activities, such as safety and health and traffic accidents. In addition, safety meetings and Safety and Health Committee meetings are held at each regional branch and business office

Initiatives Related to Safety and Health

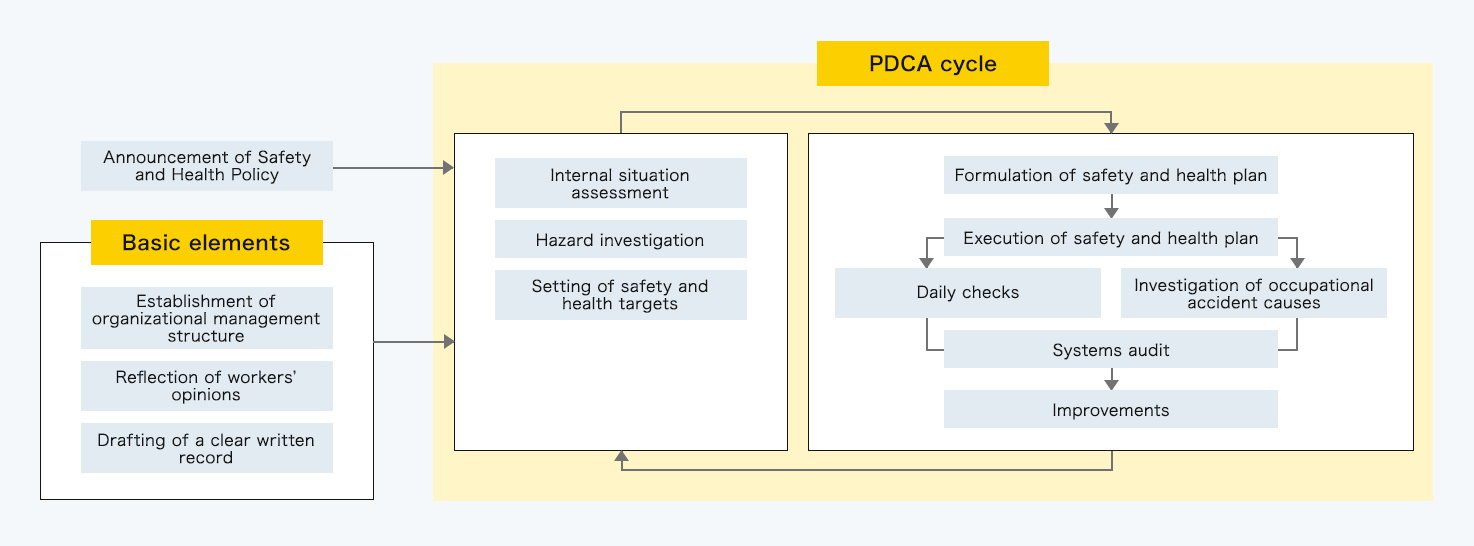

To embody the concept of safety first, business second, we are implementing safety and health activities based on safety and health management plans, aligned with our Occupational Safety and Health Management System (OSHMS), and promoting the construction of secure, safe working environments by increasing the level of workplace safety and health

Implementation of Safety Countermeasures

We verify and confirm whether people are correctly operating forklifts and tailgate lifters through audits and cyclical checks. We also regularly select hazardous points and conduct activities to improve them.

Implementation of Training and Drills

To prevent accidents, we implement safety education based on position. In addition to education aimed at managers, we aim to raise safety awareness for all workers through methods including meetings covering “Zero Work-Related Accidents campaign” and “Safety Awareness Day.”

Manager Education

Yamato Transport provides education to employees who have been appointed as site managers or legal management supervisors (safety management supervisors or health management supervisors), using an internal video platform. Through case studies of internal accidents and results of supervisory inspections, legal managers can gain a deeper understanding of their own roles.

Meeting Regarding Measures to Promote Occupational Safety and Health Management System

At Yamato Transport, we have been holding meetings to exchange opinions on occupational safety and health management with some branch office managers and safety officers. We presented case studies on Occupational Safety and Health Management System (OSHMS) implementation methods and measures that aim to prevent recurrences of occupational accidents to increase the safety awareness of employees.

Training for Newly Appointed Operational Managers

At Yamato Transport, training for employees appointed as operational managers is conducted according to the timing of their appointment (four times per year). The training aims to increase the safety awareness of the managers by covering laws and regulations related to occupational health and safety and case studies of what happened when occupational accidents occurred.

| Education for Development of Professional Human Resources | FY2024 |

|---|---|

| Meetings regarding measures to promote the Occupational Safety and Health Management System | 325 |

| Training for Newly Appointed Operational Managers | 138 |

| Training for Site Managers | 3,160 |

| Regular education for safety management supervisors | 2,322 |

| Regular education for health management supervisors | 2,453 |

Zero Occupational Accidents Campaign

Yamato Transport conducts a Zero Occupational Accidents Campaign in conjunction with the Zero Occupational Accidents Week conducted by the Ministry of Health, Labor and Welfare. The campaign promotes self-directed activities to prevent occupational accidents at work sites, with the aim of raising safety awareness and establishing safety activities. With the goal of creating workplace environments that enable each worker to work safely and with peace of mind, the program sets out key initiatives for the entire company and engages a PDCA cycle to establish measures and promote safety and health activities. During a preparatory period in the lead up to the program, site managers and legal management supervisors refresh their knowledge of safety and understanding of their duties via e-learning.

Each day during the campaign period, they gather and share examples of occupational accidents. After the program, they are required to examine the causes of occupational accidents and measures to prevent recurrences. They aim to increase safety awareness throughout the entire company.

Safety Emphasis Day

Yamato Transport has designated the third Wednesday of every month as “Safety Emphasis Day.” This is a day for all employees to review themselves to check whether they are putting safety first in their daily activities, and to take steps to prevent occupational accidents and traffic accidents, both as a company and systematically on key points for each business site. After Safety Emphasis Day, safety meetings are used to review Safety Emphasis Day initiatives.

Prevention of Accidents

To prevent accidents at each office, we have been advancing the introduction of even safer facilities and equipment and the enhancement of education for workers. Should an accident happen, we aim to prevent re-occurrence by analyzing causes, taking measures, and verifying their effectiveness through audits and cyclical checks.

Preventing Contact Accidents with Materials Handling Equipment

We conduct training on operation of forklifts and tailgate lifters and install fixed barricades to prevent contact between materials handling equipment and pedestrians.

Introduction of Safety-Enhanced Equipment

To prevent occupational accidents during materials handling operations, we have introduced safety-enhanced equipment. By fixing the operating boundary for materials handling equipment and restricting the opening of roll box pallets during raising and lowering, we aim to increase safety.

Additionally, we have launched a scheme that allows drivers to wear sunglasses to improve visibility during driving and reduce the risk of eye damage. We will continue advancing initiatives that improve the safety and health of our employees.

Preventing Occupational Accidents Caused by Vehicles

To prevent drivers from falling from the cargo decks of trucks, we are installing handholds.

We are also installing handholds on truck doors to prevent finger entrapment.

Unification of On-Premises Sign Display Rules

In order to prevent occupational accidents associated with the handling of roll box pallets and forklift work, we have clarified areas of operation for forklifts and designated safe routes for pedestrians. We have also established common standards for safe routes, areas of operation for forklifts, and lines of movement for roll box pallets —specifying details such as the colors, widths of markings, signs, and installation locations—and unified rules for signs and markings on premises.

Measures Against Heatstroke

The risk of heatstroke has been increasing year on year due to the impact of climate change.

Yamato Transport has implemented various measures to reduce the onset and severity of heatstroke in daily life and during work. Specifically, we have developed a working environment with air coolers and spot coolers installed in sorting areas and salt candy and salt tablets prepared for employees. Additionally, we have created a manual about heat stroke countermeasures and carry out training to spread awareness of heat stroke alerts and the reporting flow for heat stroke incidents.

In fiscal 2025, we have introduced equipment to measure the Wet Bulb Globe Temperature (WBGT) heat index, expanded the introduction of cooling fan vests, and launched testing of wearable devices for employees that sense heat stroke risks.

Rapid Accident Response

Should a serious accident occur, we have created a communication network to rapidly share information with management.

Group Company Safety Initiatives

Each company in the Yamato Group conducts safety initiatives suited to its own business activities. Please see the website of each company for details.